Meeting the Needs of Today’s Cold Chain Logistics Through Temperature Monitoring

Within two and a half weeks of each other late last year, three big-name pharmaceutical companies—Pfizer (working with BioNTech), Moderna, and AstraZeneca—produced viable COVID-19 vaccine candidates. When it was reported that the Pfizer vaccine had to be kept at a frigid -70 °C, many experts predicted its difficult storage requirements would pose a distribution challenge that inevitably could lead to waste.

Another area of concern lies in the food industry where the United States has been established as the global leader in food waste. It’s been reported that Americans discard nearly 40 million tons of food every year. That’s 80 billion pounds of food which equates to 30-40 percent of the country’s food supply. And while personal food waste is a leading contributor to these disturbing numbers, approximately 12 percent of all food waste occurs during distribution when room temperature changes often take place.

Both the pharmaceutical and food & beverage industries are part of what’s known as cold chain logistics. Temperature-sensitive products like chemicals, meat, plants, drugs and vaccines require temperature-controlled environments from production to consumption and every step in between. Temperature consistency ensures the quality of these products as they move through their respective supply chains. Unfortunately, ensuring temperature consistency is often challenging.

The good news is that determining whether consistent temperatures have been effectively maintained is much easier today due to advancements in the cold chain itself as well evolving technology and tracking capabilities.

Temperature monitoring can save the pharmaceutical and food & beverage industries thousands of dollars per year in lost or spoiled goods. With a temperature monitoring system in place, distribution fleets can keep an accurate record of temperatures within trucks in order to prevent lost loads and maintain high quality customer service.

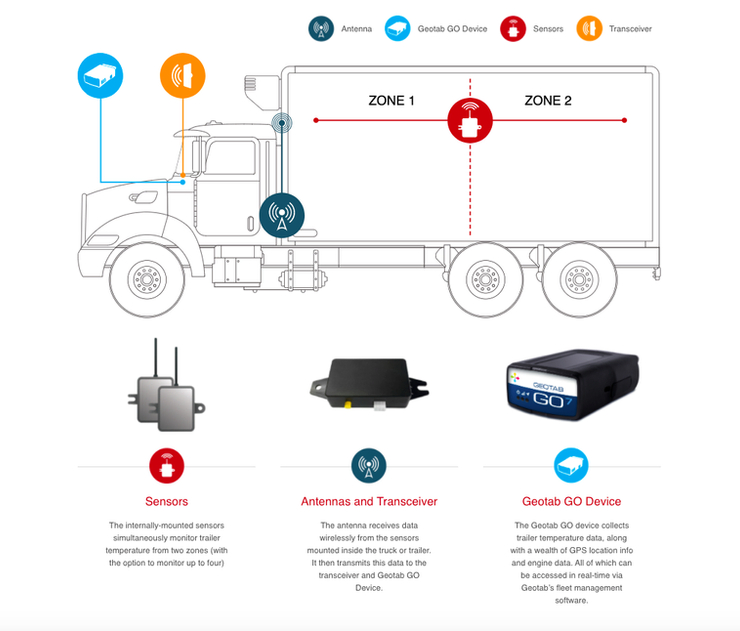

Wirelessly Monitor Up To Four Refrigerated Zones At A Time

Advantage Asset Tracking’s Temperature Monitoring ELD add-in, Advantage TempTrac, has been specifically engineered to help meet today’s demanding temperature-sensitive delivery requirements by allowing drivers to customize temperature ranges based on the type of load they are hauling. Whether it be fresh produce, frozen goods, or high-value assets such as pharmaceuticals, Advantage TempTrac ensures accurate, reliable and safe deliveries by displaying current and historical temperatures in the Geotab Drive ELD app with visual and audible alerts if the temperature goes outside of the temperature range for the type of load their hauling.

Compliance Made Easy

Our solution can facilitate Food Safety Modernization Act (FSMA) compliance as it monitors up to four zones simultaneously, and can be operated either as a stand-alone solution or seamlessly integrated through Geotab’s GO Device. From there, integration into the MyGeotab fleet tracking system allows fleet managers to monitor vehicle location and cargo temperature from one convenient platform.

How It Works

Advantage TempTrac uses four simple components to create one complete temperature monitoring solution. Once installed, monitoring temperature is as simple as it is effective. The diagram below indicates a typical setup on a reefer truck.

Features:

-

Cold chain compliant (US FSMA, EU EN12830)

-

Real-time monitoring of temperature inside the trailer, every 4 seconds

-

Immediate SMS or email alerts for over and under temperature changes

-

Track temperatures through the life of a shipment and trend temperatures over time

-

Wirelessly monitor up to 4 zones in real time (additional sensors sold separately)

Benefits:

-

Real-time monitoring removes the need for manual temperature inspection

-

Prevent spoilage of temperature sensitive loads

-

Reduce liability and number of rejected goods due to spoilage

-

Improved visibility on high value shipments through fleet tracking

To learn more about how Advantage Asset Tracking’s temperature monitoring system can help your fleet, reach out for a demo today.

Your Top ELD Questions Answered

In the U.S., ELDs are now mandatory for most commercial motor vehicle drivers to manage records of duty status (RODs), with Canada not far behind in needing to observe this requirement. The government mandates are intended to create a safer work environment for drivers. Naturally, any new implementation will yield questions from its users. Here are the most-asked questions on ELD compliance to help you save time:

1. How do you edit the HOS status Logs in Geotab Drive and MyGeotab?

In the Geotab Drive Mobile App, you can easily record HOS status and perform vehicle inspections using a phone or tablet.

If you need to edit your HOS status log:

-

Go to the dashboard and click HOS > Logs

-

Then tap the log you need to edit.

-

To select the appropriate status select the Pencil icon.

-

Add an annotation and hit Save.

Keep in mind, automatic HOS logs can be annotated, but not edited. For more information, and a full breakdown of instructions, read: How to edit HOS status logs in Geotab Drive.

Fleet managers can also edit HOS Status Logs from MyGeotab.

-

Go to Activity > HOS > Duty Status Logs

-

Select the driver and date period.

-

Tap Apply Changes.

-

Click the duty status that needs editing.

-

Select the appropriate status from the Status dropdown list.

-

Add an annotation and hit Save.

-

A pending edit has been created, and will show in yellow until accepted by the driver.

2. How does a driver log into the Geotab Drive App?

Logging into the Geotab Drive App is simple.

-

First, enter your username and password and select Log in. The system will synchronize your data before loading the main interface.

-

Select your vehicle. You can review recently driven vehicles in the Suggested Vehicles tab, or search by vehicle name, VIN, or license plate in the Find Vehicles box. (This step is skipped when connected to IOX-USB). If you do not know which vehicle you will be driving, click No Vehicle.

-

The next screen in an Assets screen. Select trailers by clicking the + icon next to Trailers, then select a trailer from the list. To add a new trailer, type its name into the Find Trailers box and then click Add. When you are finished selecting trailers click Continue.

-

To add a new shipment, tap the + icon next to Shipments, and then enter the shipment details, then hit Add. When you are finished selecting shipments click Continue. Remove any assets by clicking the X icon.

-

Hit Save and Continue once you are done selecting assets.

For a step-by-step walkthrough of these steps and further settings, such as how to add annotations, complete DVIR inspection, or how to view pending Log edits, watch the video below.

3. How do you pull an IFTA report?

Users can easily pull an International Fuel Tax Agreement (IFTA) mileage report from MyGeotab. After logging in, go to Activity and then scroll down to the IFTA Report option.

4. How do you apply Personal Conveyance?

In Geotab Drive, you can find Personal Conveyance by going through HOS > View Exemptions on the dashboard. If you do not see Personal Conveyance within View Exemptions, please reach out to an administrator to enable this feature.

Of course, we are ready to help anyone new to ELDs make a smooth and easy transition.

Contact us today at (888) 680-5833 or info@advtracking.net.

Happy Magic Hour

Join Us for Our Very First Happy Magic Hour!

Help us fight off the winter blues with an hour of family-friendly fun with Comedy Magician, Erick Olson! This free virtual event will take place on Thursday, March 11th @4:30pm EST.

As seen on America’s Got Talent, Erick Olson is a cross between Jay Leno and David Copperfield with amazing magic, comedy, visual gags and quick one-liners. Erick’s action packed show is fantastically entertaining and will keep you hooked all throughout.

Advantage Asset Tracking wants you to get a great laugh and big cheer right before the weekend. If you like magic, Erick’s show will leave you scratching your head and asking “How did he do that?”

This free event will take place LIVE on Thursday, March 11th @4:30pm EST.

Click HERE TO REGISTER for the event.

The Latest on Heavy-Duty Fleet Electrification (Part 2)

We have been posting a number of blogs on the electrification of fleets across industries with an emphasis on the heavy-duty fleet sector. Without a doubt, the electrification in transportation is an inevitability and with reason: not only does it lead to technological advances that increase efficiency but it also offers an essential response to environmental and sustainability concerns.

We covered both the barriers and benefits of the electrification of heavy-duty fleets in our last blog post (link to Blog Post C). Now we turn our attention to the implications of adding electric models to heavy diesel industries, among other updates on the advancement of heavy-duty fleet electrification.

Air Quality and Health

Much of the air pollution in lower-income communities comes from the diesel trucks that move products to and from nearby industrial areas. Diesel emissions are also a major source of nitrogen dioxide which prevents these areas from achieving air quality levels necessary for good public health. The state of California estimates that their new electric truck mandate could prevent 900 premature deaths in these communities and deliver $9 million in public health benefits.

Impact to Grid

Electrification of the heavy-duty sector presents unique challenges and opportunities compared to light-duty EVs. With considerably larger batteries and higher charging rates, if left unmanaged, charging heavy-duty vehicles could have negative impacts on the grid. However, implementing smart charging systems can reduce these impacts. Mechanisms such as off-peak electricity demand charging, dynamic controlled charging and vehicle-to-grid (V2G) could all help to mitigate the impact of electric trucks (eTrucks) and electric buses (eBuses) on peak demand and reduce electricity generation capacity needs.

Oil Demand and GHG Emissions

Even though trucks represent less than 5% of the global vehicle stock, their high fuel consumption and mileage means that they are responsible for over a third of global diesel demand and 3% of total global energy demand. The electrification of these trucks would therefore have a significant impact on overall diesel and oil demand. Across all vehicle weights, it is estimated that EVs will displace 4.3 million barrels of oil per day by 2030. GHG emissions are closely related to fuel consumption, and medium- and heavy-duty trucks are responsible for a sizable share of total GHG emissions. As diesel drivetrains give way to electric, the resulting fall in GHG emissions will be considerable.

Government interventions to accelerate the transition of heavy-duty transport to electric

California is the first state to approve specific legislation to accelerate a large-scale transition of zero-emission medium- and heavy-duty vehicles. The Advanced Clean Trucks (ACT) Regulation was passed by the California Air Resources Board to help the state meet its mandates to reduce air pollutants, in order to protect public health and meet climate change targets.

The regulation requires that manufacturers who certify Class 2b-8 chassis or complete vehicles with combustion engines would be required to sell zero-emission trucks as an increasing percentage of their annual California sales from 2024 to 2035.

Seven other states and the District of Columbia have signed a statement of intent to pursue a similar medium- and heavy-duty zero emission vehicle initiative.

The importance of varied EV model support for complete fleet management

As fleet and sustainability managers make their long-term plans for fleet electrification, it’s vital to select a fleet management platform that can support the greatest range of makes / models, and that has the capabilities to accommodate the most new EVs as they come to market.

Geotab has been independently ranked as the number one commercial telematics vendor for two years running. And with support for over 100 electric vehicles, it’s the strongest telematics provider in the EV space.

It’s likely that managers will initially have to operate a fleet consisting of both electric and conventional vehicles. The fleet management platform must therefore be able to work with all drivetrains, so that performance data such as mpg and mpg-e can be directly compared. The platform also needs to be able to collect electric-only data such as battery state of charge, to ensure optimal performance and maximum ROI during the transition to an all-electric fleet.

Our Geotab fleet management platform offers the widest make / model support of all EVs, from light- to heavy-duty, to support your fleet today and into tomorrow.

(Article source: https://www.geotab.com/white-paper/heavy-duty-fleet-electrification-trends/)

The Latest on Heavy-Duty Fleet Electrification (Part 1)

In a recent blog post we talked about the five electric commercial truck companies we are watching in 2021. Today we will go deeper into the latest trends we are seeing in the heavy-duty fleet category. Although this segment of the commercial vehicle market is still young, the world’s largest manufacturers have made it clear that they see electrification as an increasingly important piece of the freight transportation industry.

Just in the past few years, we have started to see an increase in market share of electric trucks (eTrucks) and electric buses (eBuses). Most of the major Original Equipment Manufacturers (OEMs) and several start-ups are preparing to launch their respective battery electric or fuel-cell/battery models in 2021/22, and the electric bus market is already well established in the U.S. With the early adoption of EVs, fleet and sustainability managers can get ahead of stringent emission regulations, which will make it inevitable that transit agencies, school districts and logistics companies deploy cleaner fleets.

Barriers (and Benefits) to Electrification in the Heavy-duty Sector

With such new technology, naturally there will be challenges to adoption. We note the most obvious ones below. We also highlight some of the benefits to adopting electrification in the heavy-duty sector as these certainly will offset the barriers through further technological advances and challenges being addressed.

Range

One of the greatest challenges facing heavy-duty electric vehicles is range. Trucks are intended to haul heavy trailers and loads, which are demanding tasks that contribute to quick battery drain. Load weight is another consideration in the heavy-duty sector. The benefits of eTrucks will certainly depend on load weight as a factor, as it can potentially result in higher electricity consumption and shorter range capability. Load capacity claims from OEMs suggest that they will be capable of matching today’s load standards, but they will require real-world data to prove this out.

Charging times

In order to counter the issue of range, manufacturers currently have to use larger, or more, batteries. The larger the battery capacity, the longer it takes to charge. Most eTrucks will take well over two hours to fully recharge on the fastest available charging systems, and some vehicles will have to plug in overnight to fully recharge a drained battery.

Carrying capacity

For a given GCWR (gross combined weight rating), electric trucks can’t carry as large a payload as their diesel counterparts, because their tractor weighs significantly more. This can leave the trucks with a several thousand pound shortfall in carrying capacity. This results in logistics companies needing more eTrucks to do the same amount of work as their conventional alternatives.

Now let’s look at the benefits of an electrified heavy-duty sector:

Improved torque

A feature that’s unique to eTrucks is instant torque, or the ability to deliver peak torque at zero RPM. This enables electric trucks to tow and haul a large payload at much lower speeds than their conventional counterparts.

Reduced maintenance requirements

Although pure electric vehicles require some scheduled maintenance for their electrical systems, this is minimal compared to that required for their ICE counterparts. This is because a pure electric vehicle has far fewer moving parts than a combustion engine, and no oil or transmission fluids to replace. Brake systems also last longer than for conventional vehicles, thanks to their regenerative braking systems.

Environmental noise reduction

While rolling noise remains a constant when comparing electric heavy-duty vehicles with their ICE counterparts, the propulsion noise is considerably lower without a combustion engine. This makes the biggest impact when vehicles operate at low speeds, as they most frequently do in urban areas, where noise pollution is the greatest concern.

Reduced Total Cost of Ownership (TCO)

In the U.S. long haul market, McKinsey predicts that medium- and heavy-duty trucks will reach TCO parity with diesel in the early 2030s. In urban operations, light-duty trucks and eBuses will have achieved parity by 2025, and medium-duty trucks pre 2030.

In our next blog post, we will cover the implications of adding more electric models to heavy diesel industries and the importance of EV model supports for successful fleet management transitions.